Pistons are designed with features which perform specific functions during engine operation. The piston head or crown receives the majority of the initial pressure and force caused by the combustion process. The piston pin area is exposed to a significant amount of force due to rapid directional changes. It is also subjected to thermal expansion caused by the transfer of heat from the head to the body of the piston. The piston pin area is subject to more thermal expansion than other areas of the piston. This occurs from the thermal expansion properties of cast aluminum alloy and the mass in the piston pin area.

Some pistons are cast and machined at the factory into a cam ground (elliptical shape). An elliptical shape is an oval shape in which one-half is a mirror image of the other half. These piston shapes provide an advantage in conforming to the ever-changing dimensions of the cylinder bore. The piston is designed to be an elliptical shape when cold. As the engine reaches operating temperature, the piston pin bore area expands more than other thinner areas of the piston. At operating temperature, the piston shape becomes a circular shape, which matches the cylinder bore for improved sealing and combustion efficiency.

Some pistons are designed with a taper, with the smallest diameter of the taper at the piston head. The taper shape compensates for thermal expansion and thermal growth. Thermal growth is the increase in size of a material when heated, with little or no change back to original dimensions. The taper design allows the piston to move freely in the cylinder bore regardless of the heat applied to the piston head.

Some Briggs & Stratton engines use a barrel-shaped piston skirt. The barrel shape provides a smoother transition during directional changes of the piston. The piston rolls into the cylinder wall when changing direction at the end of a stroke. This reduces noise, spreads the force of the directional change across a greater surface, and reduces side loading on the piston skirt.

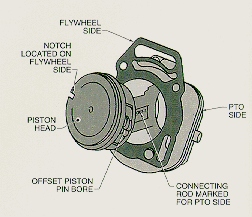

Some piston designs have the piston pin offset from centre in the piston. The proper orientation of the piston pin offset is marked by a notch or an arrow on the piston head. The mark on all Briggs & Stratton pistons should be facing or closest to the flywheel on all one- and two-cylinder engines. The offset piston pin design offers a quieter running engine by reducing piston wobble and related noise. This results in truer linear movement of the piston in the cylinder bore.

Each piston design must have a provision for returning oil to the oil reservoir and the crankcase. During operation, a significant amount of oil is accumulated in the piston oil ring groove. This oil is returned to the reservoir through piston windows or through a machined channel near the piston pin.

Piston windows are a series of small holes machined into the oil ring groove surface of the piston. The oil ring collects excess oil from the cylinder bore. Piston windows allow oil in the oil ring groove to drain into the oil reservoir.

Another common method used to return oil to the oil reservoir is through a machined channel near the piston pin. Oil collects in the rear of the oil ring groove and is routed back to the oil reservoir through the channel ending at the piston pin. This provides a path for oil to return to the oil reservoir along the outside surface of the piston when the machined channel is exposed to the oil reservoir at BDC.