|

| Sustainable Dwelling Regeneration |

| jump to: | systems and materials| applications | bio-climatic design | refrences |

| *UNDER CONSTRUCTION!!* |

| Introduction |

Once again, Nature has flexed her muscles and hundreds of thousands are displaces and homeless. These people are now facing the huge tasks of dealing with their loss and rebuilding their lives from the sand up. The process of rebuilding that has started is a very sensitive and complex one. Millions of dollars of aid are coming in and several relief organizations are stepping up to help the rebuild process. This project is designed to maximize the amount of aid given by exploring sustainable, alternative building technologies, while looking at traditional Indonesian building methods and customs. Rebuilding sustainably will help protect the already stressed environment and possibly create a more comfortable living environment. Completely modern prototypes will be presented while some prototypes modifying traditional housing types with alternative methods and materials will be explored. Also, several technologies are presented in a manor in which they can be applied to several building types and sites. For example, if a village still wanted to build in the traditional style, some of these new technologies could be applied to that building or if a set of modular housing units were built by a relief organization the technologies could also apply to these buildings. The first section of this project reports alternative building material and systems that are applicable to Indonesia, where as the second part explores the application of these technologies and materials at different scales and sites.

|

| Systems and Materials |

| jump to: | modular contained earth (earthbag) |earth-rammed tires |bamboo | |

| examples | |||

emergency shelter |

domed home | vaulted interior | vaulted home |

|

|||

*Eathbag images coutesy of calearth.org |

construction materials |

|

|

|

| bags | |

Two types of bags are available: Hessian (burlap) or polypropylene. The polypropylene bags are the only sutable for the area of Indonesia because of the high levels of sand in the soil. The weaker the fill material, the stonger the bag must be. If only dry sand is used as a fill, the bag must be made of a non-degradable material that is strong enough to with stand dead and live loads. |

|

polypropylene

|

Polypropylene bags are made of woven plastic. Polypropylene bags will deteriorate if exposed to (UV) rays. Steps should be made to protect the bags from sunlight both before and after construction. UV resistant bags are also available, however more expensive. In the United States, manufacturers sell the polypropylene bags for around 22 cents per year plus delivery. The sacks are available in a variety of widths. |

reused bags |

Recycled seed or feed sacks made of polypropylene can be obtained from factories or stores that bag these products. The bags can be sewn together to increase the length. |

| fill | |

| A typical adobe mix of sand and clay soil is ideal for earthbag construction. A mixture of sand and lime or lime-rich coral sand that would be common in these regions is also sufficient. All organic matter, rocks, and sticks should be sifted out of the soil. Any material that degrades that is left in the bags could create pockets, weakening the structure. Also remove all topsoil and only use the substrate and fill material. After the fill material is sifted and lime or coral sand is add the bags can be filled. The fill can be used either wet or dry however when using lime the fill should be moist so that the material sets for structural support. The perfect moisture content is tested by grabing a hand full of the fill and sqeezing it. It should hold its shape but not feel wet. |

|

| other materials | |

| 4-point barbed wire is laid between courses to keep the bags from slipping. As a rule of thumb, if the bag is less than 12 inches wide, only one row is needed. Two or more rows of barbed wire may be required for rows wider than 16 inches. |  |

|

||||||||||||

| construction materials |

|

| tires |

The automobile tires can be used as found. No modification to the tires is necessary. |

| fill |

| The fill for the rammed earth should consist of a mix of sand, clay and 10 percent portland cement. The fill should be moist so that the cement can set up. The moisture content is tested by grabing a hand full of the fill and sqeezing it. It should hold its shape but not feel wet. |

| tools |

| Wheelbarrows for hauling the fill, sledge hammers for compacting the earth inside the tires, and a level are all needed materials. Other helpful materials are; tampers as shown above, hoes for mixing fill, and used cans to fill the gaps in the tire walls. |

|

|||||||||||||||

| construction materials |

|

| bamboo |

Many different species of bamboo are available. From grass like species used for woven materials to bamboo poles that are 10 inches in diameter. |

| tools |

| Tools for bamboo construction is much the same as traditional wood construction. Drills for drillings holes for joints and saws for cutting the bamboo are the most necessary. Manual and power tools both work well however power tools have become much more efficient. |

| strength comparison |

| Material | Stress | Mass per Volume | Ratio |

| Concrete | 8 N/mm2 | 2400 | 0.003 |

| Steel | 160 N/mm2 | 7800 | 0.020 |

| Wood | 7.5 N/mm2 | 600 | 0.013 |

| Bamboo | 10 N/mm2 | 600 | 0.017 |

Source: Elizabeth & Adams. Alternative Construction:Contemporary Natural Building Methods |

| Applications |

jump to: equatorial house design | prototypes | |

| Basic Essentials of the Equatorial House |

| site choice |

|

| house design |

|

| Prototypes |

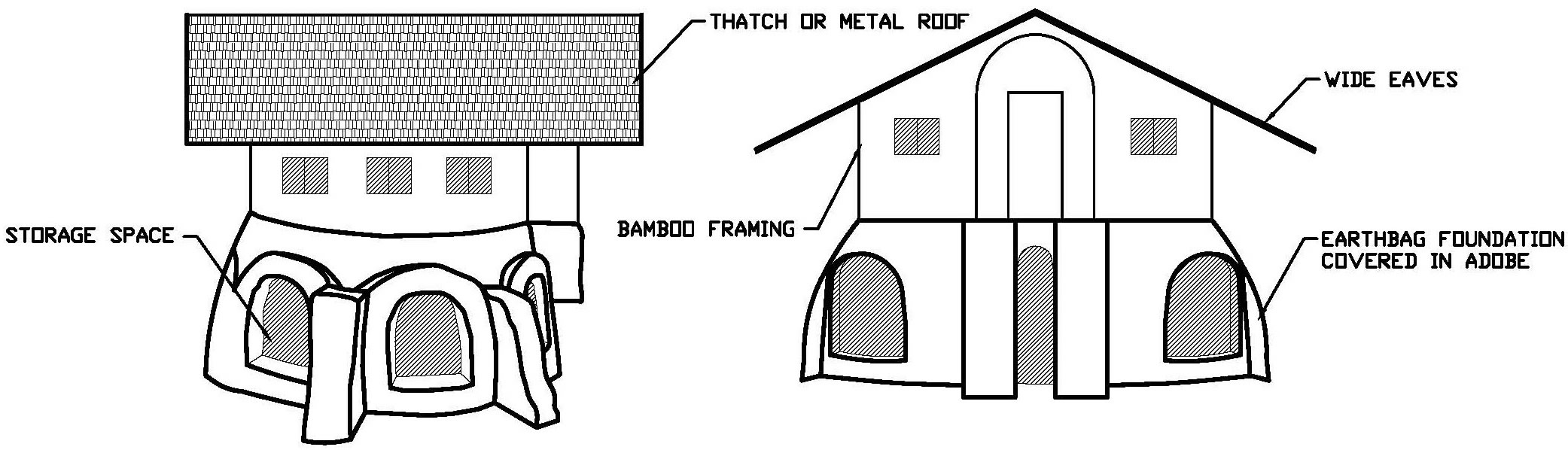

earthbag variations eco-dome |

|

|

|

earthbag foundation home |

|

|

| Bio-climatic design | |

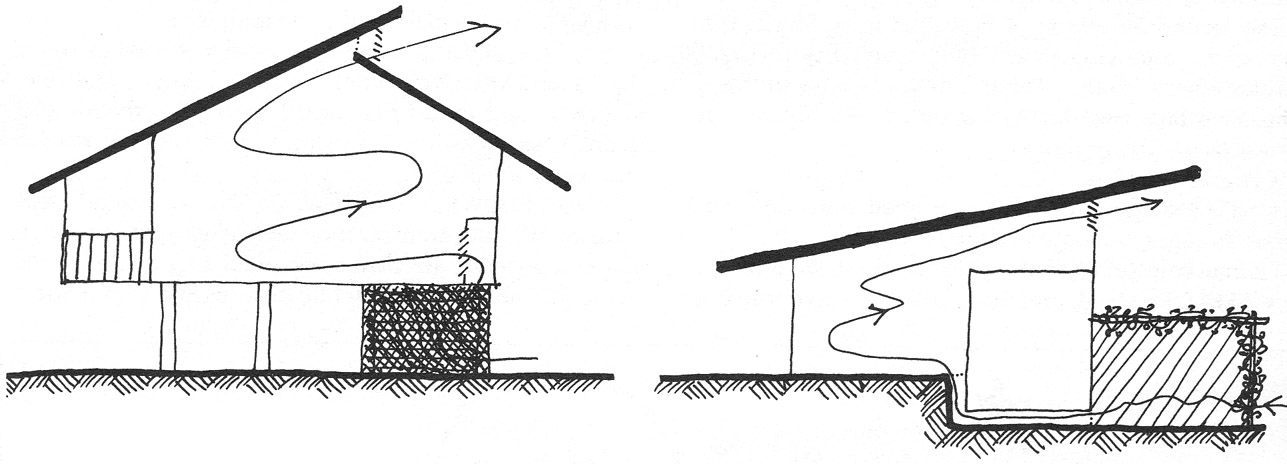

| cross-ventilation for houses | |

|

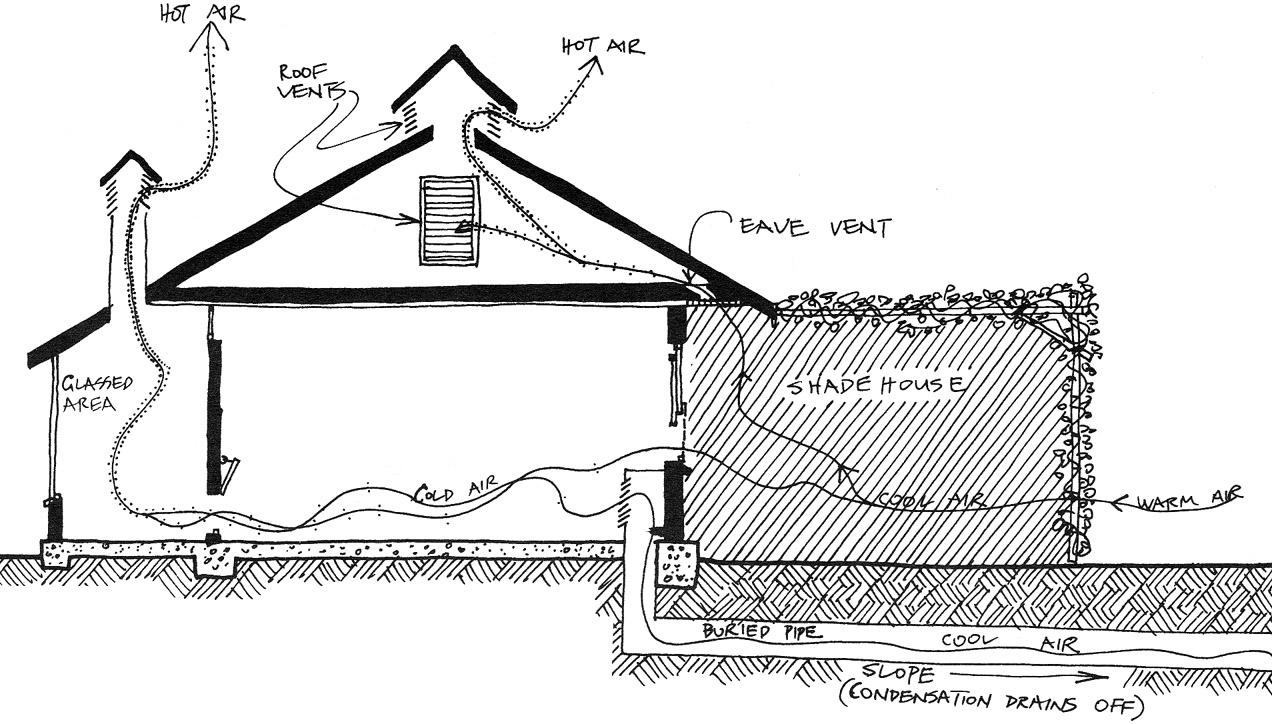

Vented ceiling slopes allow hot room air to escape, and cool trellis air to enter. (Figure Source: Permaculter A Designer's Manual by Bill Mollison.) The key to successful cross-ventilation are that the air that is flowing need to be able to follow a simple path (no corners), and that large vents are used that allow for a lot of air to pass through. |

cool air from shadehouse and buried pipe. |

|

|

A 0.5 x 0.5 m tunnel 1 m deep and 20 m long sloping to the outside intake to de-humidify and cool the air, with a solar chimney to draw air through the house. (Figure Source: Permaculter A Designer's Manual by Bill Mollison.) Metal chimneys or a hot roof (a roof that is unventilated) are the best cooling systems in a tropical house. The metal chimneys or hot roof draws in cool air from underground pipes. Being underground the earth cools the air that is in the pipes. The air that is drawn in from the pipes is more dense so it naturally sinks to the lowest level of the house but a fan can move the cool air throughout the room of the house. The cool air pipe needs to be buried at least 1 meter, and should be 15-20 meters long. The pipe should be laid at an angle that slopes away from the dwelling to allow for the condensation that develops to drain away from the house. The Outlets of the pipe should be covered with screen to keep animals out. A shade house which is a trellis covered with vegetation can also be a good for creating cool air that could be utilized by creating vents in the exterior wall of the structure and at the eaves of the roof. |

|

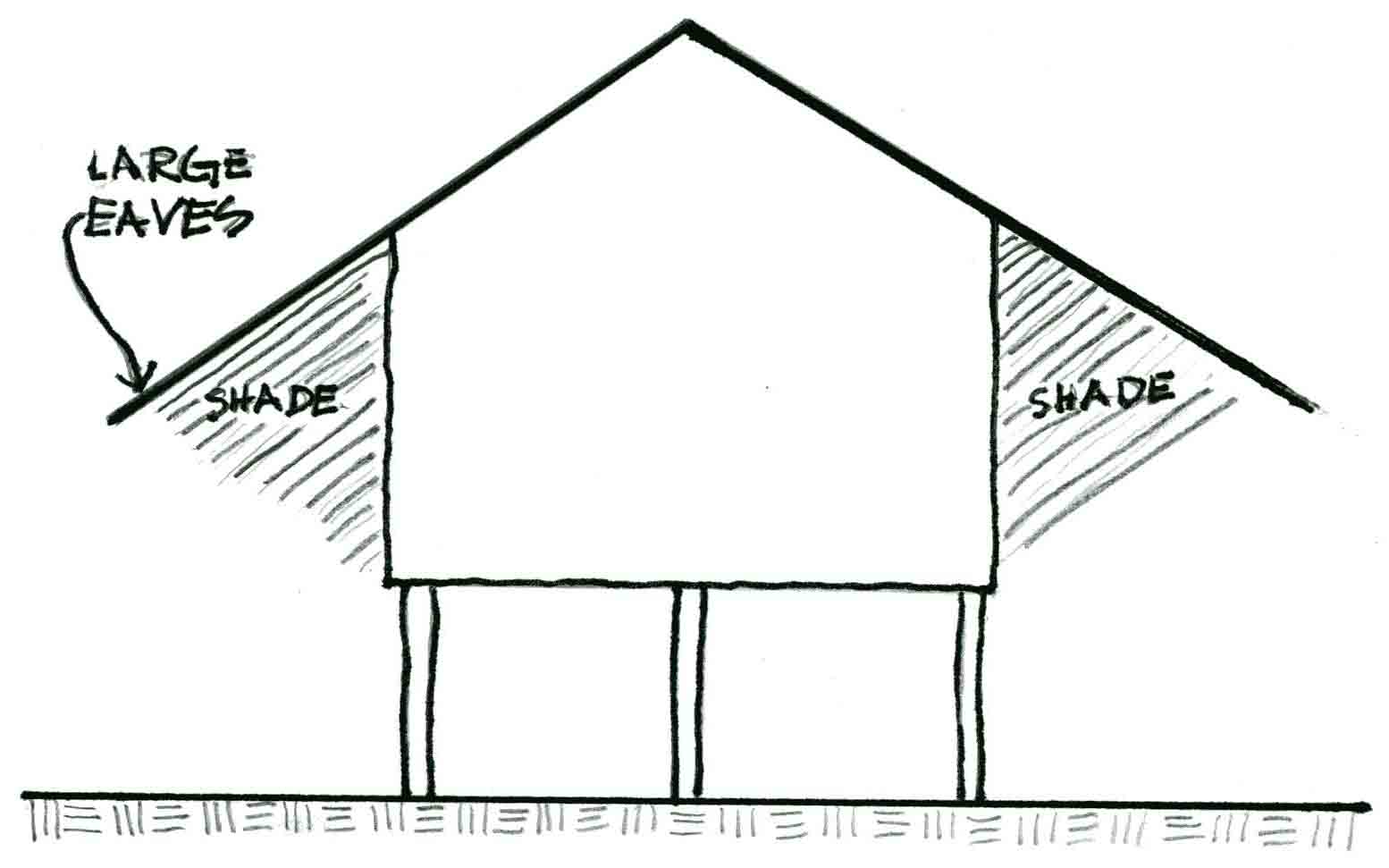

| Designing a house with large over-hanging eaves, shades the house and also brings rain water from the roof farther away from the house. |

| Refrences |

Elizabeth, Lynne, and Cassandra Adams. Alternative Construction: Contemporary Natural Building Methods. (New York: John Wiley & Sons, Inc. 2000). Mollison, Bill. Permaculture: A Designer’s Manual. Second Edition (Tasmania: Tagari Publications, 1988). California Institute of Earth Art & Architecture. 25 Feb. 2005. |