ENGR 100

Bridge Component Tests

Purpose

The

purpose of this activity is to simulate the “Research and Development”

aspect of engineering. Your team

will act as “engineering researchers” completing a series of component tests

to determine the strength and characteristics of the bridge materials.

In the end, you will compose an individual memo addressed to the design

team summarizing your findings and recommendations.

Once this is completed, you will then switch roles, becoming the

“designer”, and use this information directly to design and build your

team’s prototype bridge.

Group Assignment

The

class will work together on this assignment, with groups completing different

tests and then sharing the results. The

following is a list of tests:

Test 1 - Tension

Test

Test 2 - Compression Test

Test

3 – Torsion and Bending Test

Test 4 - Fishline Tension Test (Optional)

At

the end of class, each team will write their results (tables, graphs, findings)

on the board for everyone to copy. Each

team will then present and explain their findings and we will have a short

discussion about how these findings will be useful for bridge design.

Individual Assignment

Each

person will be responsible for writing a memo summarizing the results of the

tests and making recommendations to a fictitious design team.

The purpose of writing this memo, even though you are essentially the

design team for whom it is written, is to be introduced to the fundamentals of

technical writing.

Feel free to experiment! If you have any ideas about how to

change a test or perform additional tests, please let the instructor/TA know.

Test 1 - Tension Test

Objective

The

objective of the tension test is to determine a recommended overlap distance for

two tongue depressors in tension (taking into account strength and total span

length).

Procedure

- Build the test specimens by gluing two tongue depressors together using

different lengths of overlap ( max. < 3/4"). Be

sure to test at least 3 specimens for a given overlap distance to ensure more

accurate results. Reinforce the hole with extra pieces of tongue

depressor.

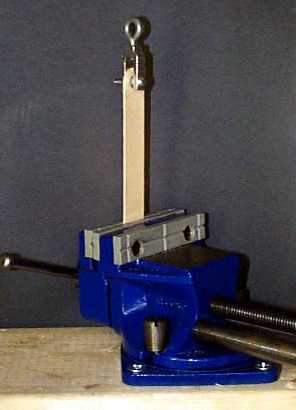

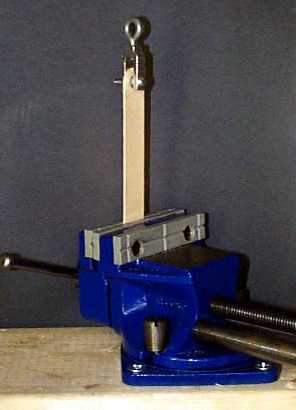

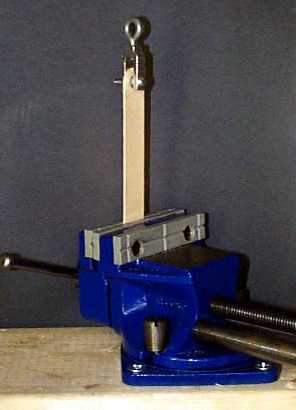

- Place the sticks in the vice on the testing platform and reinforce the hole at

the other end with tape. Test the

sticks by pulling straight up with the force gauge.

Record the forces (in lbs) required to break each of the specimens in

your notebook. Also note how each

specimen failed!

- If you are getting inconsistent results, create several more specimens and try

to standardize your testing methods.

Figure 1. Tension Test

Deliverables

(to be included in the memo)

- How

did the different specimens fail?

- Why

you think they may have failed at different places?

- What

is the relationship between failure force and overlap length?

From examining the results, what would you recommend for an overlap length?

Why?

If

you have more time…

Do

a similar test using elmers or wood glue.

How do the results compare?

Test 2 - Compression Test

Objective

The

objective for Test 2 is to determine a maximum length that designers should not

exceed, to ensure adequate strength from compressions members.

Procedure

- Use a ruler to prepare several

specimens for the compression test ranging in length from 3” to about 10”.

For members greater than 6”, glue two tongue depressors together with

a 1” overlap length and then cut the ends to the desired length.

Prepare at least 2 samples for each length to ensure some level of

accuracy.

- To

test the specimens, place them upright on the scale and push down as shown

in Figure 2 (using pliers may be easier on your hands).

Record the force (in grams) required to bend the specimen.

Convert the grams to lbs in EXCEL.

Figure 2. Compression Test

Deliverables

(to be included in the memo)

-

Does the location of the 1" overlap glue joint (end

or middle) affect the buckling strength?

-

Create a table

in Excel showing the specimen length in one column and the failure force

in another (conversion for g to lbs: Force (lbs) = (Scale Reading/1000)*9.81*0.2248)

-

Plot the Force

(lb) vs. Length (in) (For accuracy, use "x-y scatter"

graph not a line graph).

-

Look at the graph to see how the force changes as the

length changes. Is there a

particular point on the graph where the force required to buckle the specimen

decreases signficantly with little change in length?

If so, the bridge design team should be notified of this length so

they can avoid designing a bridge with compression members that are prone

to buckle under smaller loads.

Test 3 –

Torsion and Bending Test

Objectives

The

objective for Test 3 is to determine effective bracing methods to maximize

strength of a platform in bending and torsion.

Procedure

- Brainstorm different bracing methods

for a platform 11 inches long and 2 ½ to 4 inches wide.

Show sketches to the instructor or TA before you build them. See link

for examples.

- Construct several platforms using

a maximum of 16 sticks each. Each platform should have a distinct bracing method that can

be described and compared to other platforms.

Ask the TA/instructor to cut pieces using the band saw.

- Perform a

bending test on the platform by bending the ends up into a shape of a

“U”. Note the relative flexibility and strength.

- Perform a

torsion test on the platform by twisting the ends and noting the relative

flexibility and strength.

Deliverables

(to be included in the memo)

- What different

bracing methods were used?

Which were the strongest?

- Did the orientation of the tongue

depressors (flat or standing on the edge) affect the performance?

- Did the way the platforms were

constructed or number of sticks used affect the results?

If yes, how?

- What recommendations would you

give to the bridge design team for bracing?

Test 4 – Fishline Tension Test

Objectives

The objective for Test 4 is to evaluate different brands of fishline, measure their force - strain relationship and determine which brand has the highest stiffness.

Procedure

- Attach one clamp to the back of your work table.

- Obtain samples of the three (or more) brands of fishline. Approximately 45-50 inches of each.

- Tie no slip loops in the ends of the fishline.

- Measure the distance between the knots (L0).

- Apply tension loads in increments of two lbs using the force gauge and record the "stretch" length.

- Plot force versus strain for each brand of fishline using Excel. Strain is given by (L - L0) / L , where L is the "stretch" length.

Deliverables (to be included in the memo)

- What materials are the different brands of fishline? (You might need to do a little online research).

- Did the fishlines consistently break at a certain location? If so, where?

- Plot Force (lb) versus strain in Excel for the three (or more) samples of fishline.

- What recommendations would you give to the bridge design team for fishline use?

Click here

for data sheet.