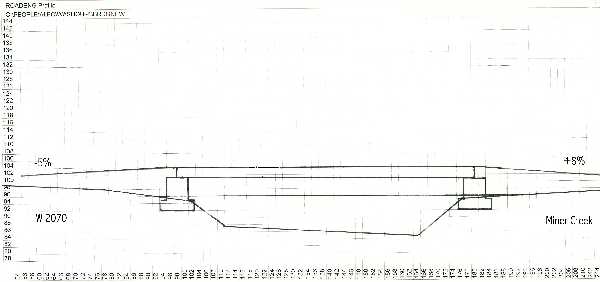

Click here for a bridge design process flowchart. GENERAL Four types of bridge designs were compared in this analysis: log stringer, glulam, prestressed concrete, and portable steel. Immediately, the log stringer option was eliminated, due to the length of the span and the required stringer diameter. Due to the structural engineering required for both the prestressed concrete and portable bridge options, the manufacturers of these bridges were contacted and estimates requested based on the design specifications. Actual engineering analysis was performed on the glulam alternative both by hand and with the aid of the USFS computer program, Timber Bridge Superstructure Rating Program. All calculations assumed the AASHTO HS 25-44 as the design vehicle, and the AASHTO U-80 as the overload vehicle. Descriptions of these vehicles can be found in the USFS Timber Bridge Manual section 6-3: Vehicle Live Load. Figure 1: Cross Section of Proposed Bridge Design

Proposed Bridge Design GLULAM In order to determine the validity of the computer model, hand calculations were computed for the three-stringer situation. The results obtained from the hand calculations were nearly identical to those obtained by the computer model. Therefore the computer model was deemed valid and used for all subsequent calculations. Using the computer model, beam size and configuration were varied and the outputs compared. The outputs compared were rating factor and gross vehicle weight for the design and critical vehicle. The goal was to minimize the number of beams, while at the same time using the smallest beam cross section possible. The hand calculations and TBSR results can be found in the appendix. Based on the above design procedure, the following specifications best fulfilled the goal of minimizing the number and dimensions of the beams, while still supporting the design and overload loadings.

PORTABLE The benefit of a portable bridge system is that it can be removed at will. If water is threatening to wash it out, or if access restriction is required, it can be removed and stored elsewhere. Another option is to use one bridge at two different crossing sites. Thereby effectively cutting the cost of the bridge in half. Two portable bridge manufacturers were compared in this analysis, Big R and Acrow. The Big R system is shipped in two pieces that are bolted together during installation. This system requires less on-site construction, but requires heavy machinery to move the bridge members. The Big R manufacture site is in Greeley, Colorado.

Figure 2: Big R bridges in use and being installed

The Acrow system is shipped in pieces no larger than 10 feet square. The main advantage of this system is it can be put together on site and rolled into place fully cantilevered. Rollers are placed on both banks and the span is simply rolled into place. The Acrow plant is located in Carlstadt, New Jersey.

Figure 3: Major Components of the Acrow Bridge

Both systems would be covered with a wood plank running surface, and curbs. Estimates were obtained from both companies, and the purchase, delivery, and installation costs were compared. The lifespan was assumed to be the same for both systems, 50 years. We requested bids from both companies, but niether replied to our repeated requests. Therefore, we excluded them from our recommendation. When contacting these companies you may reference conversations with Eric Farm of the University of Washington. They should have a file started as estimates were requested and multiple phone conversations took place over the course of this project. These companies can be reached at: Big R Manufacturing

Acrow Panel Bridges

PRESTRESSED CONCRETE Due to the limited number of companies that manufacture prestressed concrete bridge components in the Northwest and high costs associated with delivery, the closest manufacturer to the proposed bridge site was contacted for information and an estimate. This company was Morse Bros. Prestressed Concrete Group which is located in Harrisburg, Oregon.

Figure 4: Example of Prestressed Concrete Bridge Deck MBPCG estimated this bridge to be $35 per square foot. Past experience has shown that the cost of purchase, delivery, and installation is roughly $1000 per lineal foot. Based on our design specifications of 16 ft x 80 ft, the prestressed concrete will cost approximately $80,000. This design calls for a precast, prestressed concrete slab. The lifespan of this system is estimated to be 100 years. It should be noted that since 1950 when these bridges were first installed, none have failed. Thus, an accurate lifespan is very hard to estimate. As with the portable bridges, this company has started a file and reference to Eric Farm at the University of Washington should get both parties on the same sheet. This company was extremely interested in this project and would like to be contacted as this project is put up for bid. The contact at Morse Bros. is: Bob Knorr

|